BendPak

BendPak 10APX-181 Two Post Lift 10,000 lbs. Capacity

- SKU:

- 5175307

- Availability:

- FACTORY SHIPPED

- Minimum Purchase:

- 1 unit

- Shipping:

- Free Shipping

Description

![]()

BendPak 10APX-181 Two Post Lift 10,000 lbs. Capacity

BendPak 10APX-181 Two Post Lift 10,000 lbs. Capacity

Adaptable, Clearfloor with Adjustable Width

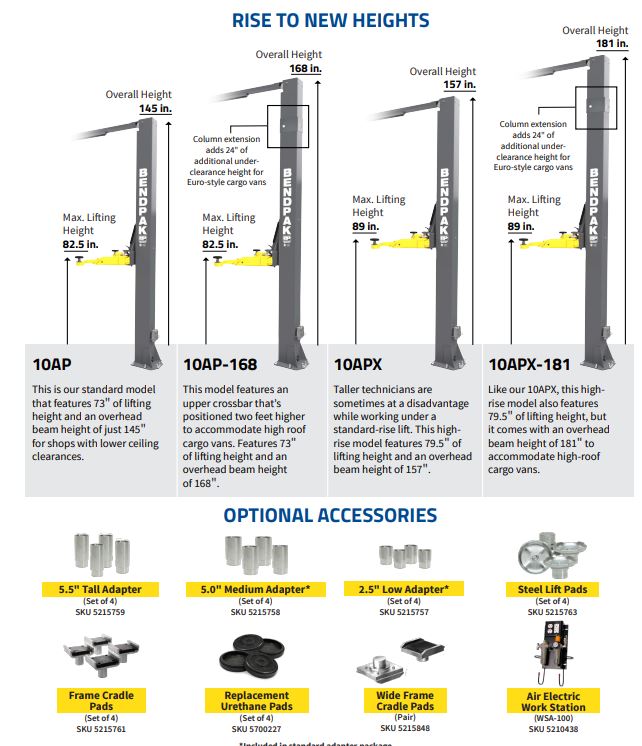

89" Max. Lifting Height, 181" Overall Height

The BendPak 10APX-181 Two Post Lift offers exceptional direct-drive lifting performance. This industrial-strength car lift guarantees cutting-edge technology, top of the line materials, a design that's ahead of its time and a 10,000-lb. lifting capacity. The 10APX Series offers the convenience of wide or narrow installation wrapped up into one configurable package. This durable, safe, and reliable car lift features an expandable top beam and BI-METRIC™ arms to suit virtually every vehicle lifting requirement - symmetric or asymmetric. The simple, yet highly sophisticated lift design keeps service and maintenance costs to a minimum, delivering lower operating expenses and higher productivity.

The 10APX-181 highrise model features 79.5" of lifting height to accomodate taller technicians and it also comes with an overhead beam height of 181" to accommodate high-roof cargo vans.

|

Model

| |||||

|---|---|---|---|---|---|

|

Capacity

|

|||||

|

Lifting Capacity: (*)

|

|

||||

|

Rise

|

|||||

|

A - Lowered Pad Height

|

|

||||

|

B - Max. Lifting Height

|

|

|

|||

|

C - Lowest Lock Position

|

|

||||

|

D - Top Lock Position

|

|

|

|||

|

Time to Full Rise

|

|

||||

|

Height Overall

|

|||||

|

E - Height Overall

|

|

|

|

|

|

|

F - Width Overall

|

|

||||

|

G - Outside Column Width

|

|

||||

|

Inside Column Width

|

|||||

|

H - Inside Columns

|

|

||||

|

I - Drive-Thru Clearance

|

|

||||

|

J - Floor To Overhead Switch

|

|

|

|

|

|

|

Arms & Pads

|

|||||

|

K - Front Arm Reach (Short)

|

|

||||

|

L - Rear Arm Reach (Long)

|

|

||||

|

Max Load Per Arm

|

|

||||

|

Electrical

|

|||||

|

Motor

|

|

||||

10AP SERIES: TALL-RISE LIFTS

Our 10APX has been designed to accommodate mechanics out there that are constantly in uncomfortable positions while on the job. This beast of a lift offers a lifting height of 79.5” and an overhead beam of 157”. This will give you plenty of room to work comfortably with the best equipment available. If you’re working on larger vehicles, our 10APX-181 is the lift for you! This lift has the same lifting height, but it features an overhead beam height of 181” so you’ll be able to work on high-roof cargo vans! Much like the rest of the 10AP Series, these lifts still have all of your favorite features, such as a 10,000-lb. lifting capacity, Low-Pro arms, Bi-Metric™ arms, and much more!

A NEW PARADIGM IN LIFTING

Auto repair shops working on the latest technology need to be equipped with the latest and most advanced tools to keep up with the wave of new vehicles. Our all-new AP series of two-post lifts sport a revolutionary design which factors the best qualities of today’s two-post lift types into a completely new concept in car lift engineering. The result is a lift unlike any other two-post lift on the market, purposefully designed for extreme use, high loads and operator safety and efficiency.

The 10AP Series offers the convenience of wide or narrow installation wrapped up into one configurable package. These durable, safe, and reliable lifts come with our advanced Bi-Metric™ arms which are capable of performing both symmetric and asymmetric lifting! The simple, yet highly sophisticated lift design keeps service and maintenance costs to a minimum, delivering lower operating expenses and higher productivity.

NEW TECHNOLOGY FOR INCREASED OPERATOR SAFETY

Throughout the past few decades, the automotive industry has always been one of the most receptive industries to emerging technologies. Technology has already redefined the way cars use fuel, with electric, hybrid, and solar energy systems beginning to displace the internal combustion engine and gas-fed engines as the driving force of the future. Forecasters are projecting Electric Vehicles (EV’s) to account for a large percentage of all vehicles produced and sold in the future, and EV’s weight considerably more than traditional gasoline or diesel-powered vehicles. Those extra pounds have important implications for mechanic safety when they’re raised in the air for service. Extra vehicle weight introduces a lot more stresses and forces on automotive lift components, especially when two-post lifts are being considered.

ELECTRIC VEHICLES ARE GETTING LARGER AND HEAVIER. ARE YOU READY?

With the emergence of heavier EV’s as the impetus for the new 10AP design, technicians are now able to service electric vehicles more efficiently, including trucks, vans, and sports cars. In addition to providing greater under-car access thanks to extremely low-profile arms and extra-wide column spacing, BendPak engineers focused on the use of high tensile-strength steels for all critical load-holding components. The increased tensile strength allowed our engineers to design swing arms with greater telescoping movement and tube profiles better suited for use on low ground clearance vehicles and outer-positioned EV vehicle lifting points. Safety-critical design enhancements are introduced throughout.

Electric vehicles need newer lifts to safely lift them due to the fact that they’re heavier because of the added batteries, reinforced framework, suspension, and the metal armor which protects the battery. From reinforced construction to purposefully engineered design features, the 10AP is the perfect EV service solution. Each 10AP model provides greater under-car access thanks to extremely low-profile arms and extra-wide column spacing; increased arm travel and minimum arm retraction allow for more versatile lift support positioning, which is perfectly suited for electric vehicle service.

AUTOMATIC ARM RESTRAINT SYSTEM PREVENTS UNPLANNED MOVEMENT

Swing arm restraints have been used for decades on two-post lifts to minimize the chance of arms shifting during vehicle loading and service. However, until now, these systems had a difficult time withstanding the excessive forces applied to them when vehicles would suddenly and unexpectedly shift on the support pads or adapters of the far-reaching swing arms; typically due to improper loading or when heavy drivetrain components are added or removed from elevated vehicles causing an unanticipated transference in the center of balance.

A significant design feature which sets the 10AP Series apart from the rest is its revolutionary Automatic Swing Arm Restraint System (ASARS)! This system is well-suited for heavy vehicle service and has been bolstered to withstand these elevated pushing and pulling forces that occur when vehicles are being serviced.

With a full 360-degrees of load-holding grip, the heavily forged-steel design of this patented and very exclusive arm restraint system secures the lift arms firmly in place with over 2000-pounds of load-holding force, preventing unplanned swing-arm movement during lift use and vehicle service operations. This revolutionary design is an adaptive system which requires minimal operator involvement and delivers unparalleled holding power. A distinctive power-hold design that allows for precise non-shifting action, and a handy quick-release operator lever allowing for the instant release of the clamping pressure.

TRIPLE-TELESCOPING NESTED SWING ARM DESIGN

Revolutionary and patented swing arms are specifically tailored for varying vehicle lifting points. Unlike traditional two-post lift arms, 10AP arms retract shorter and extend farther, offering lift operators a myriad of lift arm positioning options – it’s like having the best of all worlds!

The innovative three-stage arms achieve more telescoping movement due to their patented nesting feature that results in greater retraction and farther reach. Inner sliding arm movement is no longer impeded by arm end plates, tube closeouts, or even the arm pivot pin itself. The inner tubes retract fully through the back of the arm assembly end even beyond the arm pin, resulting in more achievable retraction and extension.

LOW PROFILE ARMS

Our exclusive Low-Pro™ swing arms feature telescoping channels which have a shorter profile and a dropped-end pad receiver resulting in better serviceability on lowered chassis-height vehicles. They access hard-to-reach lift points with less hindrance providing increased versatility and less chance of damage to vehicle side skirts, running boards or ground effects. Varying height stackable adapters combined with two stage spin-up screw pads provide greater vertical pad placement for precise and safe vehicle support.

SCREW PADS AND ADAPTERS THAT ADJUST TO YOUR NEEDS

Double-telescoping screw adapters feature gouge and tear-resistant polyurethane pads that can be screwed up or down to ensure level lifting in all conditions. Provides more precise and secure frame engagement, ensuring technician safety. 2.5” and 5” stackable adapters that are included as standard accessories provide greater vertical pad placement for precise and safe vehicle support. The drop in design allows for quick and easy use, and a column-mounted rack keeps the adapters neatly organized and secure.

INNOVATIVE SAFETY LOCK SYSTEM

The patented automatic safety lock system is designed to dramatically improve operator efficiency and safety. The simple yet innovative design ensures automatic safety lock engagement during all lift rising operations, and an ergonomic single point release allows operators to effortlessly release the safety locks during lift descent – literally all with the push of a finger. It’s just that easy.

BI-METRIC™ SWING-ARMS

Exclusive Bi-Metric™ adaptable swing-arms give users the ability to set their lift up in either symmetric or asymmetric configurations. The 2-in-1 design operators the option of loading vehicles either symmetrically (centerline of vehicle at column) or asymmetrically (centerline of vehicle behind column). By not having to switch out arms, you’ll be able to service vehicles faster than ever before.

Features & Specs

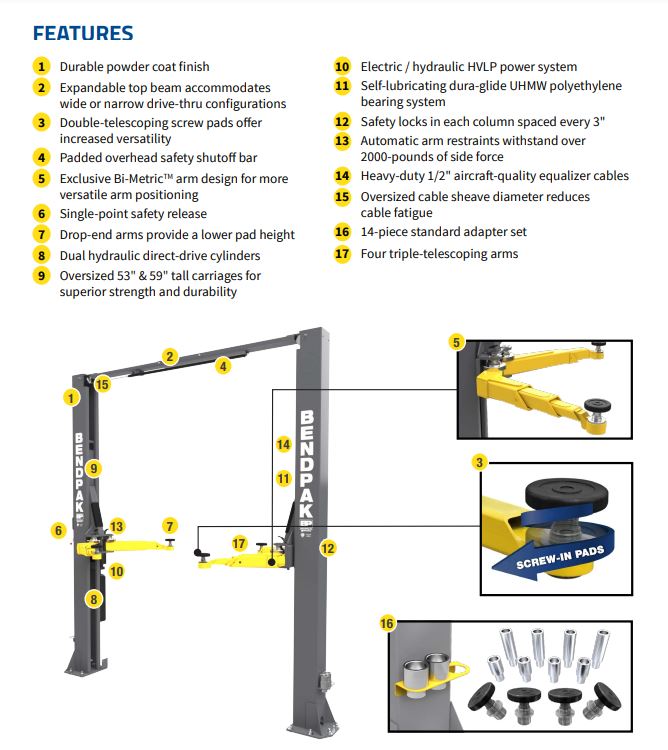

- Durable powder coat finish

- Expandable top beam accommodates wide or narrow drive-thru configurations

- Double-telescoping screw pads offer increased versatility

- Padded overhead safety shutoff bar

- Exclusive Bi-Metric™ arm design for more versatile arm positioning

- Single-point safety release

- Drop-end arms provide a lower pad heigh

- Dual hydraulic direct-drive cylinders

- Oversized 53" & 59" tall carriages for superior strength and durability

- Electric / hydraulic HVLP power system

- Self-lubricating dura-glide UHMW polyethylene bearing system

- Safety locks in each column spaced every 3"

- Automatic arm restraints withstand over 2000-pounds of side force

- Heavy-duty 1/2" aircraft-quality equalizer cables

- Oversized cable sheave diameter reduces cable fatigue

- 14-piece standard adapter set

- Four triple-telescoping arms

- ALI certified

Capacity

Rise

Outside Dimensions

Inside Dimensions

Arms & Pads

Power Unit

BendPak 10APX-181 Two Post Lift 10,000 lbs. Capacity

Adaptable, Clearfloor with Adjustable Width

89" Max. Lifting Height, 181" Overall Height

The BendPak 10APX-181 Two Post Lift offers exceptional direct-drive lifting performance. This industrial-strength car lift guarantees cutting-edge technology, top of the line materials, a design that's ahead of its time and a 10,000-lb. lifting capacity. The 10APX Series offers the convenience of wide or narrow installation wrapped up into one configurable package. This durable, safe, and reliable car lift features an expandable top beam and BI-METRIC™ arms to suit virtually every vehicle lifting requirement - symmetric or asymmetric. The simple, yet highly sophisticated lift design keeps service and maintenance costs to a minimum, delivering lower operating expenses and higher productivity.The 10APX-181 highrise model features 79.5" of lifting height to accomodate taller technicians and it also comes with an overhead beam height of 181" to accommodate high-roof cargo vans.

A NEW PARADIGM IN LIFTING

Auto repair shops working on the latest technology need to be equipped with the latest and most advanced tools to service them properly; they need to evolve alongside the vehicles they service. BendPak's all-new AP series of two-post lifts feature a evolutionary design that factors the best qualities of today's two-post lift types into a completely new concept in car lift engineering. The result is a lift unlike any other two-post lift on the market, purposefully designed for extreme use, high loads and operator safety and efficiency.Automatic Arm Restraint System Prevents Unplanned Movement

Swing arm restraints have been used for decades on two-post lifts to minimize the chance of arms shifting during vehicle loading and service. However, until now, these systems had a difficult time withstanding the excessive forces applied to them when vehicles suddenly and unexpectedly shifted on the support pads or adapters of the far-reaching swing arms; typically due to improper loading or when heavy drivetrain components are added or removed from elevated vehicles causing an unanticipated transference in the center of balance.

A significant design feature that makes BendPak's AP series particularly well-suited for heavy vehicle service is a revolutionary Automatic Swing Arm Restraint System (ASARS) that has been bolstered to withstand these elevated pushing and pulling forces that occur when vehicles are being serviced.

With a full 360-degrees of load holding grip, the heavily forged-steel design of this patented and very exclusive arm restraint system secures the lift arms firmly in place with over 2000-pounds of load-holding force, preventing unplanned swing arm movement during lift use and vehicle service operations. This revolutionary design is an adaptive system that requires minimal operator involvement and delivers unparalleled holding power. A distinctive power-hold design that allows for precise non-shifting action, and a handy quick‑release operator lever allowing for the instant release of the clamping pressure.

Triple-Telescoping Nested Swing Arm Design

Revolutionary and patented swing arms are specifically tailored for varying vehicle lifting points. Unlike traditional two-post lift arms, 10AP arms retract shorter and extend farther; offering lift operators a myriad of lift arm positioning options - it's like having the best of all worlds.

The innovative three-stage arms achieve more telescoping movement due to their patented nesting feature that results in greater retraction and farther reach. Inner sliding arm movement is no longer impeded by arm end plates, tube closeouts, or even the arm pivot pin itself. The inner tubes retract fully through the back of the arm assembly end even beyond the arm pin, resulting in more achievable retraction and extension.

Low Profile Arms

BendPak's exclusive Low-Pro™ swing arms feature telescoping channels that have a shorter profile and a dropped-end pad receiver resulting in better serviceability on lowered chassis-height vehicles. They access hard-to-reach lift points with less hindrance providing increased versatility and less chance of damage to vehicle side skirts, running boards or ground effects. Varying height stackable adapters combined with two stage spin-up screw pads provide greater vertical pad placement for precise and safe vehicle support.

Screw Pads and Adapters That Adjust To Your Needs

Double-telescoping screw adapters feature gouge and tear resistant polyurethane pads that can be screwed up or down to ensure level lifting in all conditions. Provides more precise and secure frame engagement, ensuring technician safety. 2.5" and 5" stackable adapters that are included as standard accessories provide greater vertical pad placement for precise and safe vehicle support. The drop-in design allows for quick and easy use, and 2 column mounted racks keep the adapters neatly organized and secure.

Innovative Safety Lock System

The patented automatic safety lock system is designed to dramatically improve operator efficiency and safety. The simple yet innovative design ensures automatic safety lock engagement during all lift rising operations, and an ergonomic single point release allows operators to effortlessly release the safety locks during lift descent - literally with a push of a single finger. It's that easy.

Bi-Metric™ Swing Arms

Exclusive BI-METRIC™ adaptable swing arms give users the ability to set their lift up in either symmetric or asymmetric configurations. The 2-in-1 design gives operators the option of loading vehicles either symmetrically (centerline of vehicle at column) or asymmetrically (centerline of vehicle behind column). By not having to switch out arms, you'll be able to service vehicles faster than ever before.

With Every AP Series Lift You Get...

- Clear-floor convenience - unobstructed floor space allows technicians the ability to easily move toolboxes, transmission jacks, oil drains, and other equipment underneath elevated vehicles.

- Bi-Metric™ swing arms - give users the ability to set their lift up in either symmetric or asymmetric configurations. The 2-in-1 design gives installers and operators the option of loading vehicles either symmetrically (centerline of vehicle at column) or asymmetrically (centerline of vehicle behind column).

- Low-Pro™ swing arms - low-profile telescoping swing arms offer less hindrance providing increased versatility and less chance of damage to vehicle side skirts, running boards, or ground effects.

- Automatic arm restraints - each arm is equipped with durable 360-degree full-contact geared arm restraints that provide over 2000-pounds of load-holding force and automatically engage each time the lift is raised. When the lift is lowered, the gear- type arm restraints automatically disengage to provide easy positioning of the lift arms.

- Configurable wide or narrow installation - allows you to maximize the use of your floor space.

- Single-piece columns - we purposely manufacture the columns using single-piece construction for added strength and less fatigue under heavy load conditions.

- Maintenance free load bearings - rather than using roller bearings that need constant lubrication and maintenance, every AP series lift carriage uses futuristic ultra-high molecular weight (UHMW) polyethylene load bearings that never need lubrication and last virtually the life of the lift.

- Dual Direct-Drive technology - by utilizing two low-pressure Direct-Drive cylinders, we've eliminated the need for lifting chains or screw mechanisms most commonly found on other lift designs. This Direct-Drive technology offers better reliability, smoother operation, and less maintenance. Low pressure means a much smaller workload is placed on the entire hydraulic system.

- Single-point safety release - the single-point safety release and dead-man style operation controls makes every one of our AP series lifts easy to operate and safe to use.

- On the level - our Dual-Synchro equalization system maintains equal lifting and provides operators with a stable, level vehicle working condition.

- HVLP hydraulic system - every AP Series lift uses a High Volume Low Pressure (HVLP) electric-hydraulic power system that delivers high fluid volume while maintaining low system pressure. Because the hydraulics are not constantly under high pressure, seal failure and leakages are much less likely to occur.

- Industrial-grade hydraulic cylinders - integrated into every AP Series hydraulic cylinder is a one-piece, pilot-fitted, machined-steel piston wrapped with specially designed, pressure-loaded U-cup piston seals, backups, and wear bands that virtually eliminate any fluid bypass. A micro-smooth chrome rod is machined from high-yield, ground and polished alloy steel and the welded cylinder body exceeds ASTM specifications.

- Super-tall lift carriages - 53" & 59" tall carriages are considerably taller than most two-post styles, which minimizes the stress placed on the load bearings and columns.

- Varying height stackable adapters - a 14 piece (12 adapters + 2 racks) set is included as standard accessories providing greater vertical pad placement for precise and safe vehicle support.

- Performance Guaranteed - we're so sure that our lifts will out-perform all others, we're backing that promise with a full five-year warranty. The best warranty in the business gives you more than just peace of mind; it's proof that we took a little extra care building your lift and every precaution was taken to maintain the highest degree of quality, dependability and reliability. For full details visit www.bendpak.com/support/warranty

Features and Specs

Features

- 10,000 lbs. Lifting Capacity

- Durable powder coat finish

- Expandable top beam accommodates wide or narrow drive-thru configurations

- Double-telescoping screw pads offer increased versatility

- Padded overhead safety shutoff bar

- Exclusive Bi-Metric™ arm design for more versatile arm positioning

- Single-point safety release

- Drop-end arms provide a lower pad height

- Dual hydraulic direct-drive cylinders

- Oversized 53" & 59" tall carriages for superior strength and durability

- Electric / hydraulic HVLP power system

- Self-lubricating dura-glide UHMW polyethylene bearing system

- Safety locks in each column spaced every 3"

- Automatic arm restraints withstand over 2000-pounds of side force

- Heavy-duty 1/2" aircraft-quality equalizer cables

- Oversized cable sheave diameter reduces cable fatigue

- 14-piece standard adapter set

- Four triple-telescoping arms

Optional Accessories

- #5210438 WSA-100 Air Electric Workstation

- #5175001 MLS-18 18,000 lbs. Mobile High-Lift Jack Stand

Specifications

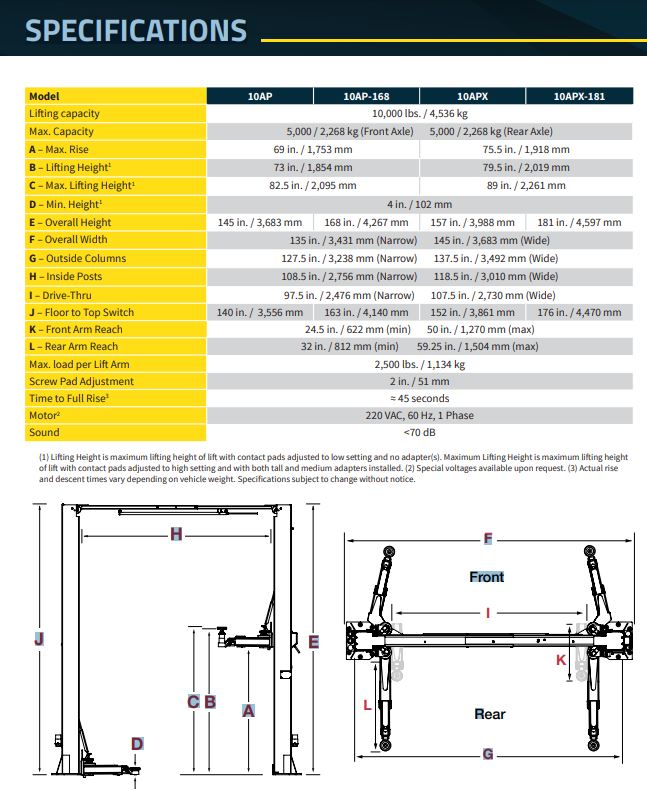

| Model Number | 10AP | 10AP-168 | 10APX | 10APX-181 |

|---|---|---|---|---|

| Lifting Capacity | 10,000 lbs. 4,536 kg | |||

| Max. Capacity | 5,000 lbs. / 2,268 kg (Front Axle) | |||

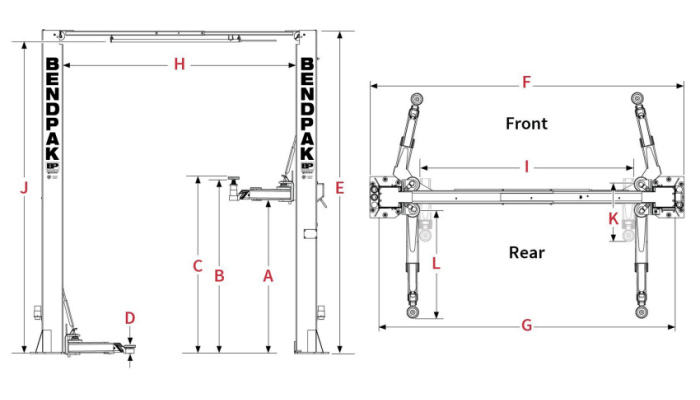

| A - Max Rise | 69 in. / 1,753 mm | 75.5 in. / 1,918 mm | ||

| B - Lifting Height | 73 in. / 1,854 mm | 79.5 in. / 2,019 mm | ||

| C - Max. Lifting Height | 82.5 in. / 2,095 mm | 89 in. / 2,261 mm | ||

| D - Min. Lifting Height | 4 in. / 102 mm | |||

| E - Overall Height | 145 in. / 3,683 mm | 168 in. / 4,267 mm | 157 in. / 3,988 mm | 181 in. / 4,597 mm |

| F - Overall Width | 135 in. / 3,431 mm (Narrow) 145 in. / 3,683 mm (Wide) | |||

| G - Outside Columns | 127.5 in. / 3,238 mm (Narrow) 137.5 in. / 3,492 mm (Wide) | |||

| H - Inside Posts | 108.5 in. / 2,756 mm (Narrow) 118.5 in. / 3,010 mm (Wide) | |||

| I - Drive-Thru | 97.5 in. / 2,476 mm (Narrow) 107.5 in. / 2,730 mm (Wide) | |||

| J - Floor to Top Switch | 140 in. / 3,556 mm | 163 in. / 4,140 mm | 152 in. / 3,861 mm | 176 in. / 4,470 mm |

| K - Front Arm Reach | 24.5 in. / 622 mm (min) 50 in. / 1,270 mm (max) | |||

| L - Rear Arm Reach | 32 in. / 812 mm (min) 59.25 in. / 1,504 mm (max) | |||

| Max. Load Per Lift Arm | 2,500 lbs. / 1,134 kg | |||

| Screw Pad Adjustment | 2 in. / 51 mm | |||

| Time To Full Rise | ≈ 45 seconds | |||

| Motor | 220 VAC, 60 Hz, 1 Phase | |||

| Sound | <70 dB | |||

- Lifting Height is maximum lifting height of lift with contact pads adjusted to low setting and no adapter(s).

- Max. Lifting Height is max. lifting height of lift with contact pads adjusted to high setting and with tall and medium adapters installed.

- Special voltages available upon request.

- Actual rise and descent times vary depending on vehicle weight.

- Specifications subject to change without notice.

- Warranty: (5) Years on Structure, (2) Year on Parts, (1) Year Labor

BendPak Two-Post/Four-Post Lifts Limited Warranty

LIMITED WARRANTY. Subject to the limitations of set forth below, Warrantor warrants that the Product sold hereunder conform to Warrantor's published specifications. WARRANTOR MAKES NO REPRESENTATION OR WARRANTY OF ANY OTHER KIND, EXPRESS OR IMPLIED, WITH RESPECT TO THE GOODS, WHETHER AS TO MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR ANY OTHER MATTER.

Duration: From the date of purchase by original Purchaser or 60-24‐12 months from the date of shipment by BendPak or whichever comes first.

- Five Years (60‐Months) Warranty on the lift structure

- Two Years (24‐Months) Warranty on the hydraulic cylinder(s) and power unit

- One Year (12‐Months) Warranty on operating components

- One Year (12‐Months) Warranty on electrical components (excluding power unit)

- One Year (12‐Months) Labor Warranty on site or at factory*

- One Year (12‐Months) Free‐Shipping** on ground‐freight charges related to warranty performance

Limited Warranty

- Who gives this warranty (Warrantor): BendPak Inc., 1645 Lemonwood Dr., Santa Paula, CA 93060

- Who receives this warranty (Purchaser): The original Purchaser (other than for purpose of resale)

- What products are covered by this warranty (Product): Any BendPak Full‐Rise Scissors Vehicle Service Lift***

- What is covered under this warranty: manufacturer defects due to material and/or workmanship with the exceptions noted below.

- What is not covered under this warranty:

- Any failure that results from Purchaser's abuse, neglect or failure to operate, maintain or service Product in accordance with instructions provided in the owner's manual(s) supplied.

- Any damage caused by overloading Product beyond rated capacity.

- Items or service normally required to maintain the Product, i.e. lubricants, oil, etc.

- Items considered general wear parts such as rubber pads/blocks, etc. unless wear or failure is a direct result of manufacturer defect due to material and/or workmanship.

- Any component damaged in shipment or any failure caused by installing or operating lift under conditions not in accordance with installation and operation guidelines or damaged by contact with tools or surroundings.

- Motor or pump failure caused by rain, excessive humidity, corrosive environments or other contaminants.

- Rusted components due to improper maintenance or corrosive environments.

- Cosmetic defects that do not interfere with Product functionality.

- Damage due to incorrect voltage or improper wiring.

- Any failure that results from improper installation or use not according to specifications.

- Damage caused by disasters such as fire, flood, wind, and lightning.

- Damage caused by unauthorized attachments or modifications.

- Responsibilities of Warrantor under this warranty: Repair or replace, at Warrantor's option, component which is defective, has malfunctioned and/or failed to conform within duration of the warranty period. Warrantor will pay reasonable labor costs for the first 12 months only.

- Responsibilities of Purchaser under this warranty/ notice of claims:

- Provide dated proof of purchase and maintenance records.

- In some cases, components may be required to be shipped to the nearest BendPak Authorized Service Center. Freight costs, after 12‐months, must be borne by the Purchaser.

- Use reasonable care in the operation and maintenance of the Products as described in the owner's manual(s).

- Immediately upon receipt of the Product, Purchaser shall inspect the same. Any claim for shortage must be made within ten days after Purchaser's receipt. All other claims, including claims for alleged defective Product, must be made within fifteen days after Purchaser learns of the facts upon which such claim is based, but in no event later than the applicable one, two or five year period specified above for the specified component(s). All claims not made in writing and received by Seller within the time periods specified above shall be deemed waived. With respect to any defects incapable of discovery until in use, all claims for any damages or losses as a result of such defects shall be deemed waived unless made in writing and received by Seller within fifteen days after Purchaser learns of the alleged defect giving rise to the claim and after the expiration of said periods, but in no event later than the applicable one, two or five year period specified above for the specified component(s). Purchaser expressly assumes all liability for all such damages or losses, irrespective of any use which shall have taken place or whether the alleged defect shall have occurred or been discovered prior to expiration of such periods.

- When Warrantor will perform repair or replacement under this warranty: Repair or replacement will be scheduled and serviced according to the normal work flow at the servicing location, and depending on the availability of replacement parts.

- *As determined by Warrantor in its sole discretion**Free‐shipping applies to direct shipping points within the 48 continental United States. Rural area shipping surcharge may apply for remote addresses. ***For all BendPak brand Full‐Rise Scissors Vehicle Service Lift (excluding specialty lifts, high rise, commercial parking, material handling, or models for particular purpose) manufactured on or following 1/1/2011.

Videos

-

My New BendPak 2-Post Lift!

In this episode we review, install and test our new BendPak XP...

-

Offset Adapters for BendPak Two Post Car Lifts

http://www.bendpak.com/car-lifts/accessories/offset-adapters.a...

-

BendPak New Two-Post Screw Pad Adapter Demo

New telescoping screw pads from BendPak fit BendPak’s new 9,00...